Conductivity sensor technology is a vital area of engineering technology study. It is commonly used in human production and living to assess the conductivity of liquids. In production and technology development, this is a must-have detection and monitoring equipment. Conductivity sensors are used to test and detect industrial process water, human drinking water, marine characteristics, and battery electrolyte qualities.

Figure. 1

Ⅰ. Types of Conductivity Sensors

According to distinct measuring principles and methodologies, conductive sensors can be separated into electrode-type conductivity sensors, inductive conductivity sensors, and ultrasonic conductivity sensors.

The electrode type conductivity sensor measures conductivity using the resistance measurement method based on the principle of electrolytic conduction, and its conductivity measurement electrode acts as a complex electrochemical system during the measurement process; the ultrasonic conductivity sensor measures conductivity based on the change of ultrasonic waves in the liquid, and the former two are the most widely used.

Ⅱ. Electrode-type conductivity sensor

1. Current status and characteristics of two-electrode conductivity sensor technology

Figure. 2

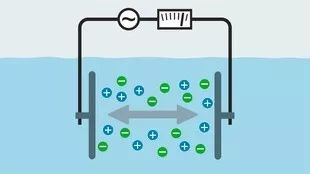

The conductivity cell of a two-electrode conductivity sensor consists of a pair of electrodes to which a constant voltage is applied. Changes in the liquid resistance in the conductivity cell cause the current of the measuring electrode to change, which conforms to Ohm's law, and conductivity is used instead of resistivity. The electrical conductivity in the metal is used to replace the electrical conductivity in the liquid, i.e., the electrical conductivity and the electrical conductivity are used to represent the conductivity of the liquid and to measure the electrical conductivity of the liquid.

The two-electrode conductivity sensor's measurement range is currently 020000S/cm, and the cell constant has distinct ranges: the cell constant is 0.01/cm, and the measurement range is 020S/cm; the cell constant is 0.1/cm, the measurement range is The range is 0.1-200μS/cm; the cell constant is 1.0/cm, and the measurement range is 10-20 000μS/cm.

The electrode of a typical electrode conductivity sensor is made up of two flat electrodes, and the electrode constant is determined by the electrodes ' facing area and distance. This type of electrode has a simple structure and production method, but it has issues such as the electric force line's edge effect and the difficulty in calculating the region confronting the electrode and the electrode spacing. A standard solution is a potassium chloride standard solution with a concentration of 0.0100 mol/L. The flat electrode is improved when combined with the conductivity cell principle, and cylindrical electrodes. point electrodes. wire electrodes, composite electrodes. and other electrodes are developed.

The electrode type conductivity sensor has the following features: 1) a simple structure and easy manufacturing; 2) a simple subsequent processing circuit and easy implementation; 3) excellent measurement accuracy, and 4) ease of use.

2. Status and characteristics of four-electrode conductivity sensor technology

Figure. 3

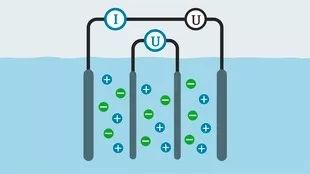

Two current electrodes and two voltage electrodes make up the four-electrode conductivity cell. The current electrodes are coaxial with the voltage electrodes, The liquid to be measured passes through the space between the two current electrodes during the measurement. Both ends of the current electrodes receive an AC signal. An electric field is created in the liquid medium by the current, and the two voltage electrodes generate a voltage to maintain a constant voltage between the two voltage electrodes, The liquid conductivity has a linear connection with the current going through the two current electrodes,

Li Jianguo of the China National Ocean Technology Center conducted research and development on the open four-electrode conductivity sensor in order to meet the needs of marine research and development, and successfully developed a four-electrode conductivity sensor for seawater conductivity measurement, with a performance index that meets the international standard. The measurement range is 065 mS/cm, and the measurement precision is O. 007 mS/cm at the advanced level.

The measuring range of the present mature four-electrode conductivity sensor is 0-2S/cm, and different cell constants have varied measurement ranges.

The following are the properties of the four-electrode conductivity sensor: 1) The current electrode is separated from the voltage electrode and is driven by a constant current source, completely eliminating the effect of polarization impedance; 2) High sensitivity and anti-pollution capabilities; 3) Number four The electrode conductivity cell is appropriate for long-term on-site measurement because of its ultra-micro structure, vast diversion space, and low distance.

3. Application of electrode type conductivity sensor

Conductivity sensors with electrodes are frequently utilized in manufacturing, life, and military applications: 1) monitoring the quality of human drinking water; 2) monitoring the quality of industrial water 3) Battery electrolyte density monitoring; 4) devices for producing electrolytic oxygen and hydrogen 5) Ocean measuring, marine resource survey, and monitoring of the marine environment.

4. Key Technologies of Electrode Conductivity Sensors

1) Elimination of the electrode polarization effect

Methods such as increasing the frequency of the power source, covering the electrode plates with platinum black, and expanding the plate area are commonly employed to reduce the measurement deviation caused by electrode polarization.

2) Elimination of capacitive effect

Two ways are commonly used to decrease the capacitance effect and improve measurement sensitivity: one is to raise liquid resistance, which is difficult to do; the other is to increase the frequency and lower capacitive reactance. However, there will be certain limitations on the frequency growth. Low-frequency is typically utilized for high-resistance, while high-frequency is typically used for low-resistance.

3) Design and manufacture of the multi-electrode conductivity cell

Each pair of electrodes in a multi-electrode conductivity cell must maintain tight symmetry and a constant distance from adjacent electrodes. placing great demands on the electrode base processing. The electrode material is mostly composed of high-performance metal, while the electrode base is mostly made of high-performance ceramic material. The expansion coefficients of the two materials differ significantly, making sintering and packaging of the electrode challenging. Sintering and encapsulation are usually done with a transition material with an intermediate temperature coefficient, although the results aren't always desirable.

5. The future development trend of the electrode conductivity sensor

1) One of the development directions for electrode-type conductivity sensors is multi-electrode and micro-electrode. Due to electrode polarization, the two-electrode conductivity sensor has a very limited measuring range and accuracy. The multi-electrode system conductivity sensor has achieved new levels of measurement range and precision. A conductivity sensor with a four-electrode configuration has been successfully created and commercialized after years of research and development. The China National Ocean Technology Center has been working on a seven-electrode conductivity sensor and has achieved significant progress in electrode structure design, sintering, packaging, and other areas.

2) To realize the automation of conductivity measurement and increase the adaptability and measurement accuracy of conductivity measurement, the conductivity sensor is combined with single-chip technology and micro-system technology.

3) Improving the shape of the excitation signal improves the accuracy and speed with which measurement data may be adopted.

4)In the case of a limited number of electrodes, the excitation sequence is optimized to get the most independent measurement data for the same conductivity distribution as possible.

6. Development of electrode materials

Because the conductivity electrode of the conductivity sensor is so specialized, there are some restrictions for the material used to produce it: 1) It has good electrical conductivity; 2) It will corrode as a result of a chemical or electrochemical reaction between the electrode and the measured media. The electrode surface necessitates the electrode's chemical stability.

Platinum, stainless steel, copper, silver, and other materials are often used electrode materials. Platinum is a great electrode material, but it's expensive. Stainless steel and metallic copper are commonly utilized as electrode materials in practical applications.

With the advancement of material science, several novel materials, such as conductive ceramics and titanium alloys, are being used to produce conductivity sensor electrodes, with promising outcomes.

Ⅲ. Inductive conductivity sensor

1. Status and characteristics of inductive conductivity sensor technology

Figure. 4

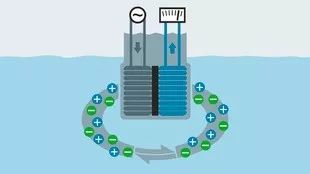

To detect conductivity, the inductive conductivity sensor employs the principle of electromagnetic induction. Within a specific range, the liquid's conductivity is proportional to the induced voltage/excitation voltage, the excitation voltage is unaffected, and the conductivity is proportional to the induced voltage.

Because the inductive conductivity sensor detector is not in direct touch with the liquid to be studied, electrode polarization and contamination are not a concern. The inductive conductivity sensor's concept dictates that it can only be used to measure liquids with a high conductivity: the measuring range is 1000-2000000 S/cm.

The following are the properties of an inductive conductivity sensor: 1) Excellent anti-pollution and corrosion resistance; 2) No electrode polarization or capacitance impact, thus it may be used to test high conductivity liquids; 3) The structure is basic and easy to use; 4) The manufacturing process is straightforward.

2. Application of inductive conductivity sensor

The majority of inductive conductivity sensors are used to measure and detect high conductivity liquids: 1) Ocean development and research, including seawater salinity measurement and analysis (deep-sea temperature, salinity, and depth profile autograph); 2) Domestic and industrial wastewater quality 3) In the chemical manufacturing process, it is used to monitor and analyze the concentration of a single component solution; 4) It is used to measure the concentration of strong acid and strong alkali.

3. Key Technologies of Inductive Conductivity Sensors

1) Sensor detector production package

Both the excitation and induction coils must be aligned on the same axis. The turns must be closely spaced in order to increase measurement accuracy, and there must be adequate shielding between the turns to limit the production of interfering coupling.

2) Excitation voltage, frequency

The inductive conductivity sensor's sensitivity and linearity are determined by the excitation voltage and frequency. Experiments are used to identify parameters such as excitation voltage and frequency based on the sensor structure so that the sensor can achieve the best sensitivity and linearity.

3) Detector miniaturization

The inductive conductivity sensor's detection is made up of a coil. The detector is miniaturized by reducing the diameter of the coil and the number of turns. The sensitivity and measuring range of the sensor will be impacted if the coil diameter and number of turns are too small.

4. The future development trend of inductive conductivity sensors

1) One of the development directions for inductive conductivity sensors is sensor miniaturization. The detector, and hence the sensor, can now be miniaturized because of advancements in material processing and preparation technology.

To automate conductivity measurement, an inductive conductivity sensor is integrated with a single chip microprocessor and microsystem technology. The controllability of the excitation signal is obtained through the use of these technologies, which improves measurement accuracy and linearity.