Deeply cultivate advanced packaging technology for vehicle mounted millimeter wave radar

In assisting intelligent driving and autonomous driving, millimeter wave radar, along with hardware devices such as LiDAR and in car cameras, plays an important role in collecting traffic environment data around vehicles. Through data collection, cars can identify road conditions clearly, making decisions based on the surrounding environment at any time, ensuring safe driving.

Compared with laser radar and camera, millimeter wave radar has all-weather detection capability. It can still work normally even in severe environmental conditions such as rain, snow, dust and fog. In addition, it can directly measure distance, speed, angle and height. It has become one of the important sensing devices in intelligent assisted driving and automatic driving. Currently, L1/2 autonomous vehicle are usually equipped with 1-3 millimeter wave radars, which is expected to grow to L4/5 in the future, It will be equipped with over 10 millimeter wave radars.

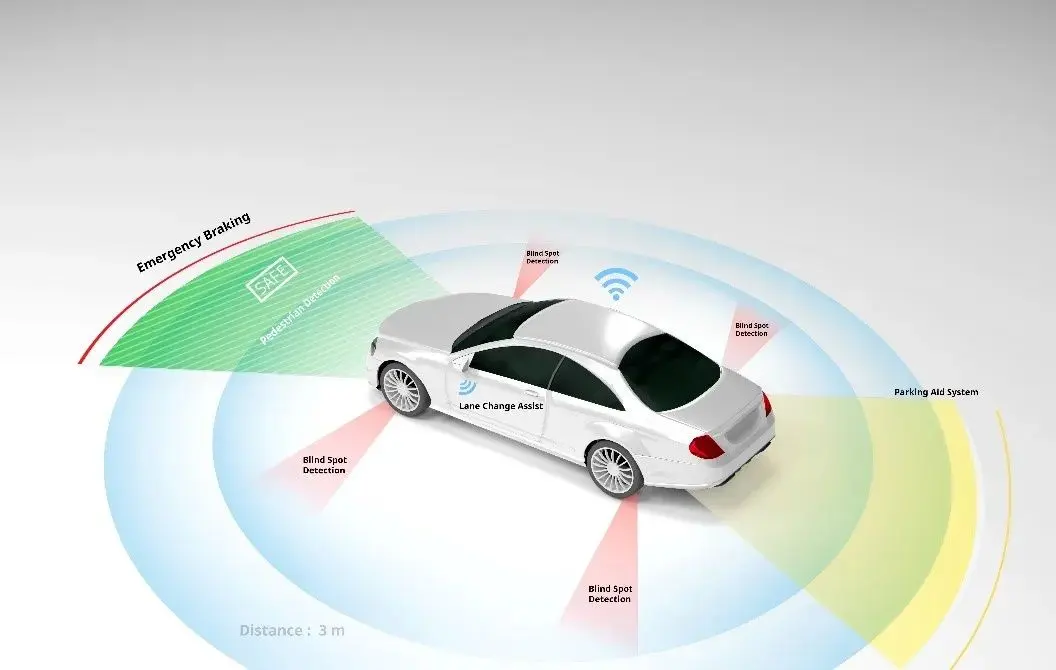

Application distribution map of millimeter wave radar

According to Yole's market research forecast, from 2021 to 2027, the compound annual growth rate (CAGR) of the automotive radar product market will reach 14%, reaching a scale of 12.8 billion US dollars. Among them, the millimeter wave radar market, including 4D products, will reach 8 billion US dollars, with a CAGR exceeding 40%. Various automobile component manufacturers have launched related products to compete for market share.

With the improvement of autonomous driving level, millimeter wave radar products are also gradually developing, including longer detection distance, higher detection dimension (3D → 4D) detection, finer angle detection resolution, higher frequency, more material integration, faster computing power, etc. In order to meet the corresponding requirements, higher requirements have been put forward for chip packaging technology, such as higher integration, lower interconnect inductance, and lower costs.

Traditional wire packaging, due to the high inductance of the wire, is difficult to meet the requirements of high-frequency products. Therefore, the packaging forms of millimeter wave radar chips mostly use flip chip packaging and fanout packaging.

Chip flip chip packaging is the process of making metal bumps on the chip pad, flipping the chip and directly connecting it to the substrate, shortening the connection length to achieve faster connection and lower power consumption;

Fan out packaging, which leads out the circuit by reconstructing the wafer and then wiring, reduces the overall packaging thickness while eliminating the need for a substrate, thereby reducing the total packaging cost;

Due to the need for integration, the AiP (Antenna in Package) packaging of integrated antennas and radar transceiver chips is gradually being adopted by users. AiP can reduce the overall product size and shorten the connection path, effectively improving product performance, and will gradually become the mainstream packaging form of millimeter wave radar products in the future.

Changdian Technology currently has mature chip flip chip (FCCSP) packaging and fan out (eWLB) packaging, as well as AiP packaging testing solutions, and has achieved mass production of car grade products. Meanwhile, in recent years, Changdian Technology has collaborated with well-known customers in the industry to develop AiP SOC products for on-board millimeter wave radar transceiver chips and integrated antennas. The company also provides advanced packaging and mass production solutions for 4D millimeter wave radar to more customers, meeting the increasingly diverse customized development and technical service needs of automotive electronics customers.

In terms of product development, Changdian Technology can provide technical support services to customers in packaging collaborative design, simulation and packaging reliability verification, material and high-frequency performance testing, as well as high resolution and low power consumption of customer products. Changdian Technology has various process capabilities in AiP packaging related to integrated antennas, as well as profound material selection experience and process control capabilities in enhancing heat dissipation and product warpage control.

We have been deeply involved in the field of related packaging and testing technology for many years, and Changdian Technology currently has many mature solutions, as well as the ability to customize and jointly develop packaging technology suitable for customer needs. In the future, Changdian Technology will continue to maintain close cooperation with customers, continuously expand solutions with high cost-effectiveness, high integration, high-density interconnection, and high reliability, and provide high-quality products and services to global customers.

Changdian Technology is a leading global provider of integrated circuit manufacturing and technology services, providing a comprehensive one-stop service for chip product manufacturing, including system integration, design simulation, technology development, product certification, wafer in wafer testing, wafer level mid channel packaging testing, system level packaging testing, chip product testing, and providing direct shipping services to semiconductor customers around the world.

Through high integration wafer level (WLP), 2.5D/3D, system level (SiP) packaging technology, and high-performance flip chip and lead interconnection packaging technology, Changdian Technology's products, services, and technologies cover mainstream integrated circuit system applications, including network communication, mobile terminals, high-performance computing, automotive electronics, big data storage, artificial intelligence and the Internet of Things, industrial intelligence, and other fields. Changdian Technology has six production bases and two research and development centers in China, South Korea, and Singapore, and has business institutions in over 20 countries and regions. It can closely cooperate with global customers and provide efficient industrial chain support.