Precautions for auxiliary power supply of electric vehicle chargers

With the popularity of electric vehicles, electric vehicle chargers have become ubiquitous, to the point where legislation now requires new residential and industrial buildings to have charging points. Although the main power conversion technology is an innovative field, it also requires low-power auxiliary AC/DC and DC/DC converters. This article will discuss the specifications that these low-power auxiliary converters need to meet.

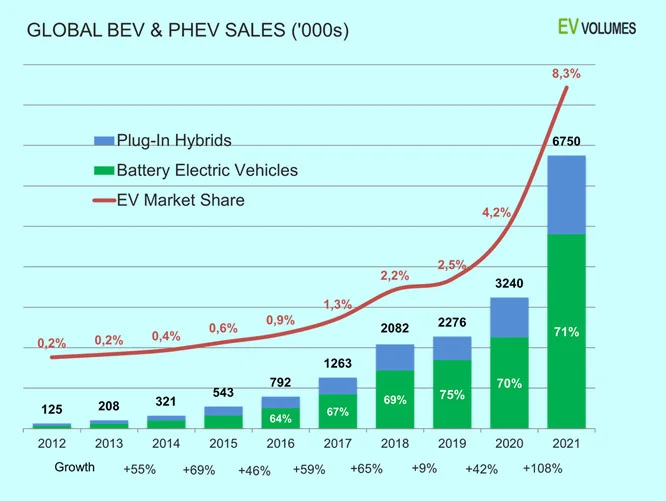

Various forms of electric vehicles (EVs) have become increasingly popular. According to data from "EV Volumes" (Figure 1), global sales reached 6.75 million vehicles in 2021, an increase of 108% compared to 2020.

The driving factors behind this growth are obvious: increased environmental awareness, rising fuel prices, and government set carbon dioxide emission reduction targets. In the UK, certain laws will come into effect in 2022, which will require each new residential building with a parking space to have a charging point. At the same time, several European countries have proposed laws prohibiting the sale of new pure gasoline and pure diesel vehicles, which have been advanced from 2040 to 2035. Public charging stations are also rapidly being launched, with more and more functions. For example, starting from June 2023, new charging stations in Germany must be equipped with debit or credit card readers for ease of use.

Therefore, the complexity of chargers can range from simple in car slow charging (household single-phase AC power supply) to ultra high speed DC fast charging (powered by industrial three-phase AC) with multiple processors and interfaces to control power transmission and security functions, as well as providing security reporting and billing services through the "cloud".

Electric vehicle chargers require auxiliary power supply

Each DC charger requires an auxiliary power supply. Although a few kW power main converter can generate low power auxiliary power, which may come from the winding of the PFC inductor, doing so is usually not a wise choice for various reasons. For example, when unloaded, the low efficiency of the main power converter of a DC charger can cause significant losses. Therefore, if standby requires an auxiliary power supply, it is best to obtain it from a low-power AC/DC converter and simultaneously turn off the main converter to reduce losses. Low power AC/DC converters can exhibit high conversion efficiency when used as auxiliary power sources. In addition, having an independent auxiliary power supply makes the startup and shutdown of the main converter safer and more reliable. The use of independent low-power AC/DC converters can also provide isolated power supply for other functional circuits in the system, which helps to avoid grounding loops, EMC issues, and interface safety issues. Of course, isolated or non isolated DC/DC converters can be connected in series to the back end of the auxiliary AC/DC converter, and adjusted to generate the required working voltage for each functional circuit and meet the requirements of noise level.

The harsh environment where the charger is located

The auxiliary AC/DC and DC/DC converters of EV DC chargers must overcome specific environmental challenges, and they are generally expected to have a long service life and a certain degree of reliability. The device requirements should be at least "industrial grade" and also meet specific standards, such as EN 61851-23 "Electric Vehicle Conductive Charging System: DC Electric Vehicle Charging Station".

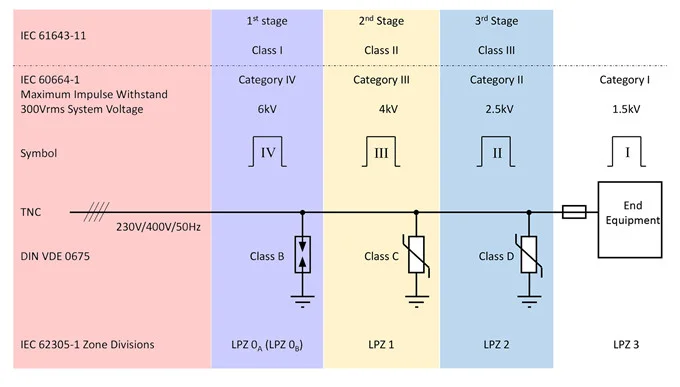

This standard covers many fields and references other documents, but specifically states that the power supply of EV chargers and chargers must comply with Overvoltage Category (OVC) III or IV. At present, most industrial grade AC/DC converters on the market do not meet the requirements, as they were usually designed with reference to Class II standards in early designs. OVC refers to transient overvoltage generated by lightning strikes, for example; According to IEC 60664-1, the relevant pulse voltages are summarized and explained in Figure 2.

Figure 2: Overvoltage Categories (OVC) for Different Standards

From the input of the building to the terminal equipment of the distribution system, surge protection devices (SPD) are shown in Figure 2 (Class B, C, and D), which can consume/absorb the pulse energy of surges. The unlabeled Class A SPD is a part of the low-voltage distribution system, and Class B is characterized by a 10/350 µ s current waveform, typically using gas discharge tubes. The characteristic of Class C SPD is an 8/20 µ s current waveform, while the characteristic of Class D is a combination of a 1.2/50 µ s voltage waveform and an 8/20 µ s current waveform. Class C and D usually use metal oxide varistor (MOV), and there is always a Class C in front of Class D. The service life of MOVs is limited, and the clamping voltage will decrease with each surge until it approaches the normal working voltage, and the leakage current will continue to increase until overheating occurs and a fault occurs. Due to this reason, MOVs used in SPD typically use DIN rail format, which allows for a visual indication of their health status.

When installing EV chargers (especially public chargers), if the environment belongs to OVC IV, we can expect SPD to downgrade the level to OVC III and provide AC power to the main power converter in any case. However, this cannot guarantee that only the AC/DC power supply of OVC II can work safely and reliably. Therefore, any auxiliary AC/DC power supply usually needs to have the ability to withstand the transient voltage of OVC III, Based on this, most commercial power sources are currently not suitable. There is also a relationship between the safety gap required for the overvoltage level of any equipment and the altitude. When the altitude is below 2000m, there is no need to consider the correction factor, but at higher altitudes, the electrical gap must be gradually increased, for example, a x1.48 multiplication factor is required for 5000m. Sometimes this important consideration may be overlooked, but there are 8 countries in the world with capitals with elevations exceeding 2000 meters, and there will definitely be EV charging stations in the future.

Safety standard for auxiliary power supply of electric vehicles

The current version of EN 61851 23:14 still references EN 60950-1 as a safety standard, although it was outdated by the end of 2020 and replaced by EN 62368-1, which is usually acceptable in electric vehicle applications. However, users need to verify the exact specifications required. For example, EN 61851-1 requires safety isolation transformer to comply with IEC 61558-1. EN 62368-1 considers this standard as an additional option, despite its limitations. Therefore, AC/DC that already has IEC 61558-1 certification is a safer choice. The power supply certified according to IEC/EN 60335-1 is also suitable for chargers with a maximum output of 120VDC, such as plug-in hybrid vehicles or electric scooters with 48V or 72V batteries.

The AC power supply voltage of the EV DC charger will be determined by the location of the application, which may be 115/230VAC for household single-phase, 400VAC for industrial/commercial three-phase, or 480VAC. The low-power auxiliary AC/DC converter for three-phase power supply is usually connected to the phase line and neutral line, and needs to operate at a nominal voltage of 277VAC in a 480VAC system. Some low-power AC/DCs can directly operate at maximum phase to phase voltage in a 480VAC delta system, up to 528VAC.

The Physical Environment of Electric Vehicle Chargers

EN 61851-23 specifies the minimum environmental pollution level for EV DC chargers, which is PD3 for outdoor use and PD2 for indoor use. However, if it is in an industrial area, it must also be PD3. The definition of PD3 pollution is as follows: "There is conductive pollution, or dry non-conductive pollution becomes conductive due to condensation." In fact, this means that electronic devices must have coatings or packaging, or significantly increase the creepage distance to avoid malfunctions and voltage breakdown in humid, dirty, or dusty environments, which are the most common environments in garages or open parking spaces.

The thermal rating of the EV charger device must also be matched with potential harsh environments, such as temperatures below zero degrees Celsius and outdoor sunlight above 60 degrees Celsius. Usually, an "industrial grade" AC/DC power supply with an ambient temperature of -40 ° C to+85 ° C is sufficient.

Provide ready-made modules

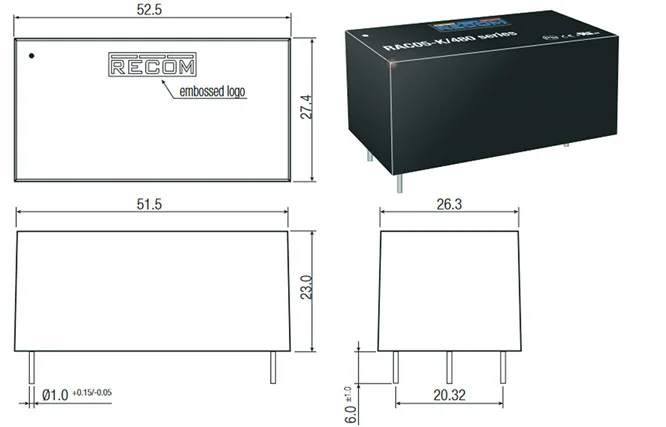

Although the requirements for low-power EV DC chargers are complex, RECOM offers a range of ready-made products suitable for various applications. RAC series AC/DC modules with 3W to 40W micro packaging modules for high pollution environments. In addition to the "standard" input range of 85-264VAC, some models have a nominal input voltage of 305VAC for 277VAC, while RAC05-K/480 has a rated input voltage of up to 528VAC (Figure 3). The working environment temperature of all AC/DC modules ranges from -40 ° C to at least+80 ° C, meeting OVC III level or optional. All AC/DC modules provide complete security certification, with IEC/EN 62368-1 being the minimum requirement. Some modules pass home certification IEC/EN 61558 or EN 60335-1, while some even pass medical certification IEC/EN 60601-1.

Figure 3: RECOM RAC05-K/480 with a rated input of 528VAC, compliant with OVC III level

RECOM can also provide a complete range of DC/DC converters, suitable for gate drive power supply of main inverters, isolated communication interfaces, isolated auxiliary power supply, and non isolated converters. These converters all have robustness and high quality to operate in harsh environments.

Conclusion

EV DC charging is an emerging market with special technical requirements. Cost and size are also driving factors, but RECOM's products not only match modular AC/DC auxiliary power supplies, but can also be used in conjunction with general-purpose DC/DC converters.